With regard to achieving the goals of the NEC guidelines, it is hoped that there will be great potential in manure treatment, which means that the first practical system for examining manure additives went into operation at the HBLFA Raumberg-Gumpenstein in October 2020. In specially manufactured manure tanks, which are housed in an air-conditioned container complex, different manure additives can be measured and examined under practical conditions. After verification and standardization of the test containers and the measurement technology, the first product could be examined. Particular attention was paid to measurement accuracy, error-free measurement and optimal statistical data evaluation. A product from the “rock powder” category was examined. The product is intended to reduce ammonia and odor emissions. This is to be achieved through its special composition and a particularly fine grind. Manure from cattle fattening was used, which showed no abnormalities according to the manure analysis. According to the manufacturer, the product should be stirred in and then all the manure should be spread out, as the effect should be active in the first 1-1.5 hours. The measurement period lasted eight days, during which all parameters were measured.

- Ammonia_NH3 (ppm)

- Methane_CH4 (ppm

- Nitrous oxide_N2O (ppm)

- Hydrogen sulfide_H2S (ppm)

- Carbon dioxide_CO2 (ppm)

- PH value

- Manure temperature (°C)

- Air temperature (°C) in the calming zone

- Humidity (%) in the calming zone

- Air speed (m/s) in the calming zone

Data evaluation

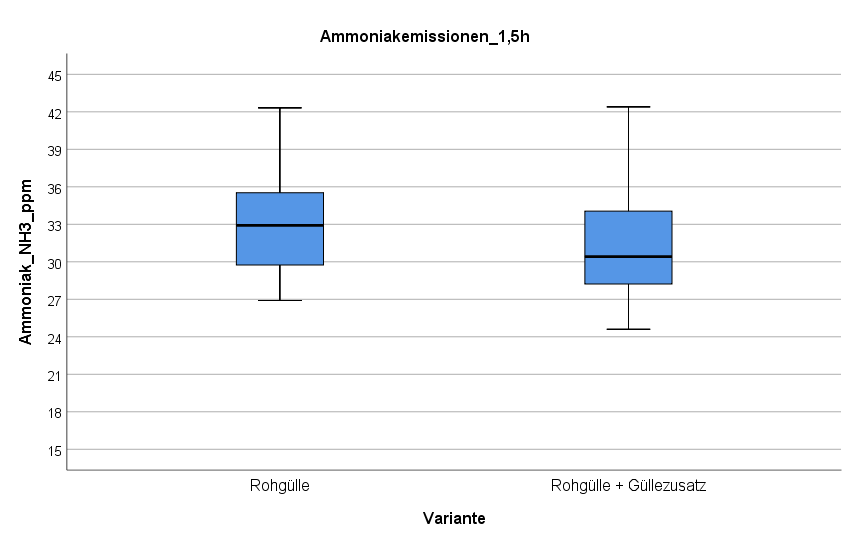

The evaluation of the data referred to the desired 1.5 hours after stirring the product into the liquid manure. Both variants “raw slurry” and “raw slurry + slurry additive” are shown in the figure.

Figure: Box plot of the two variants raw manure and raw manure + manure additive, measured in ammonia in ppm in the period 0 - 1.5 hours after the addition ( HBLFA Raumberg-Gumpenstein, 2021).

Measured in terms of ammonia (measured data in ppm-parts per million), this is indicated on the Y-axis. The two variants can be compared in the form of boxplots. A slight reduction in ammonia emissions can be seen using the “raw manure + manure additive” variant. However, the statistical analysis did reveal any significant difference

Conclusion

The product is safe to use and a “slight” reduction in ammonia can be assumed immediately after addition, but this requires complete homogenization in the slurry pit - this will be followed by another measurement run. An important point to discuss is its use in practice. In most cases, emptying a slurry pit within an hour is not possible, and emptying it completely all at once is not practical.

A possible reduction in odor emissions could not be demonstrated in this experiment due to the prevailing Corona situation, as this would have required several people in a small space.

We are already working on further product tests and hope for further exciting results.