Current state of research on important effects

It is of central importance that you can take advantage of short periods of good weather and avoid crumbling losses, which is often easier when growing silage. But fermentation losses in storage are also significant; ventilation hay preservation has advantages here. Several independent research results show that feed digestibility and feed intake are higher with good hay than with grass silage, to the extent of approximately 1 kg dry matter per cow per day. It is easy to explain why something different is often heard and read about the feeding effect: This effect only applies ceteris paribus, for example if the hay was harvested from the same vegetation stage (“on the same date”).

Drying hay usually requires more working time. However, the difference is often only 10% of the annual working time required for basic feed production, so it doesn't make much of a difference overall. As a simple example: of course hay is turned more often, but time is saved elsewhere, for example when compacting it.

Current test runs

Hay ventilation systems are energy-intensive, which is why the HBLFA Raumberg-Gumpenstein has been testing for years, and again this year, how the technical efficiency can be improved. Through the optimization, the specific energy consumption of the entire system (dehumidifier and blower) was reduced from around 500 W/kg to an average of 350 W/kg of water to be dried. This increase in efficiency was achieved by consistently recirculating air using a roll-up tarpaulin on the box edges and by insulating the roof skin that lies above the drying box.

How does this work out for companies?

The mere fact that both processes, hay and silage, have become established shows their business relevance. Of course, the marketing of hay milk plays a role, but the cornerstones of operational management are far more important. One of the central conditions is always the “ability”, the competence of the people involved, regardless of whether they are preparing and feeding hay or grass silage. If the management is right, a procedure can be more profitable.

It is therefore not possible to say generally what constitutes the economic viability of hay milk production. Rather, it generally depends on how well the management of all areas of your own dairy farm is going, as the areas are inextricably linked.

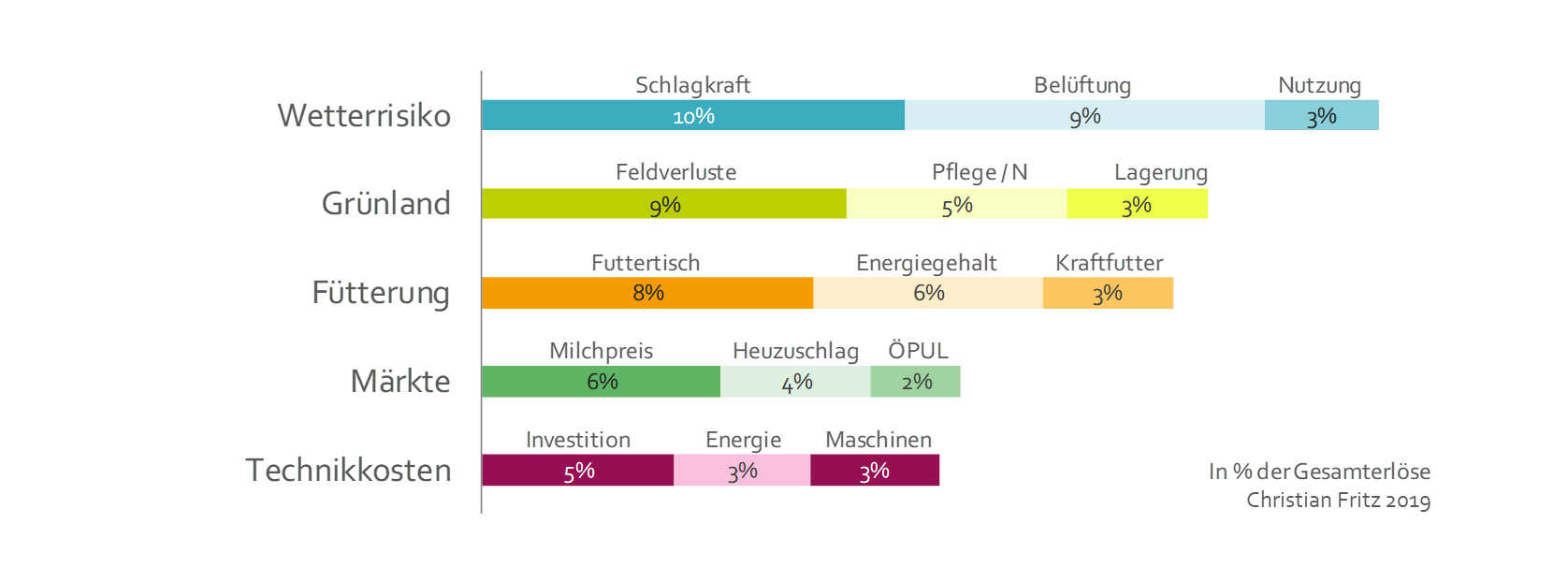

Which operational areas are of great importance? The figure provides an answer to this. Using a medium-sized Austrian hay milk farm, it shows how important certain influencing factors can be for profitability.