On the one hand, there has been a noticeable increase in temperatures in the last two summers, and on the other hand, the animal populations need optimal conditions in terms of the stable climate in order to maintain their health and make the best possible use of their performance potential. Additional measures such as spraying water (or adding liquid aerosols) have a variety of effects and, in addition to reducing dust, also enable the compartments to be cooled. Appropriate technologies are necessary for this and an innovation is currently being tested in an animal welfare stable for fattening pigs in Lower Austria, with the main aim being to improve the climate indoors (rest zone) in order to ensure functional safety in summer.

Technology

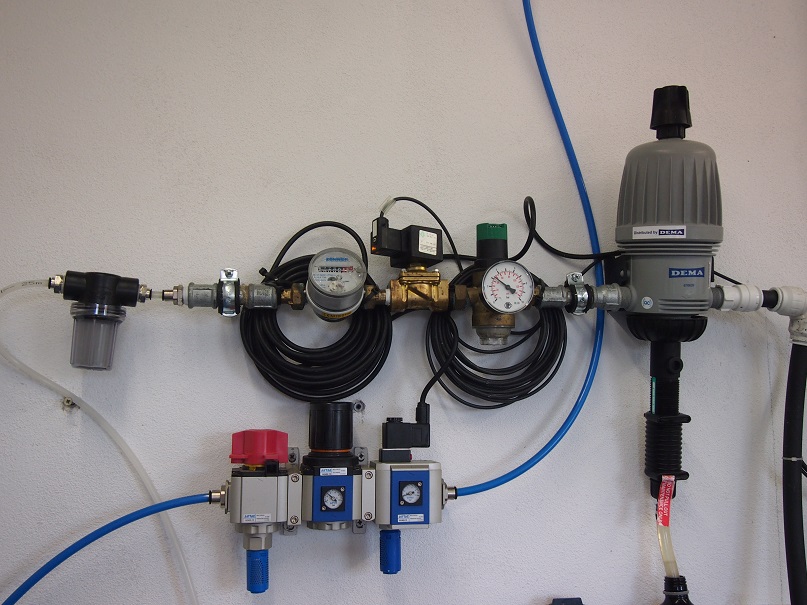

The system has a modular structure - connections as well as the control and regulation unit are placed in a technical room, the "spray heads", which achieve an area coverage of approx. 50 m² with up to 4 nozzles in 4 directions, are installed in the stable. Additionally, 2 lines are required (liquid or compressed air, each with approx. 3.5 or 2.5 bar), which are connected easily and without tools using a standardized plug-in system. On the one hand, the liquid is forced through the nozzle by its own pressure, and compressed air is also used to accelerate the drops at the end of the nozzle. The two-substance nozzle system has proven itself to be able to achieve a permanent droplet spectrum of approx. 15 microns (corresponds to a very fine mist). The system technology is designed in such a way that a dosing option for concentrated additives (bronchial elixirs, essential oils, etc.) is provided after the water supply.

First results

Out of 22 days of measurement so far, there were outside temperatures above 30°C on 7 days (maximum value 34.6°C). The technology was able to compensate for these temperature increases very well with a spray interval of 30 minutes controlled via a temperature sensor and a spray duration of 30 seconds each, especially in the afternoon hours. Temperatures of up to 31.1°C only occurred on two measuring days - the average temperature was indoors at 25.36°C. The temperature reduction of the technology used resulted in differences between inside and outside of up to 4 Kelvin.

With regard to the dust measurement data, the results of the preliminary investigations carried out in February were confirmed again. After a short-term increase in particles due to the spraying process, there was a significant reduction in dust content of up to 80%.

Conclusion

Keeping the effects of climate change and structural change in mind, it is becoming increasingly important to adapt stables efficiently to the needs of the animals - the goal is climate-fit stables for the future!

Further information is available from aero-solutions Umwelttechnik GmbH (