This project aims to evaluate methods that will enable non-destructive measurement of beef quality. Specifically, it involves measuring electrical conductivity and pulse impedance, which, like other meat quality parameters, change during meat maturation. In addition to comparing conductivity and pulse impedance with meat quality parameters at the same maturation time, it should also be checked whether it is possible to predict meat quality 14 days after slaughter (recommended minimum maturation time for beef) by measuring conductivity 2 days after slaughter.

Previous studies have shown that conductivity and pulse impedance measurements represent potential options for assessing meat quality at the slaughterhouse.

Such measurements have already been and are used in pig slaughtering to detect meat quality defects (e.g. PSE meat). To date, however, there are only a few experimental results on the use of such devices in cattle slaughter. In addition, such methods have usually only been

tested on one category of cattle (calves, bulls, etc.) in previous experiments. In the present project, the suitability of this measuring device is to be examined for all categories slaughtered in Austria (young cattle, calves, oxen, bulls, cows). The applicability of this measurement method in all categories is an important prerequisite for possible use in practice.

Specifically, the following goals are pursued:

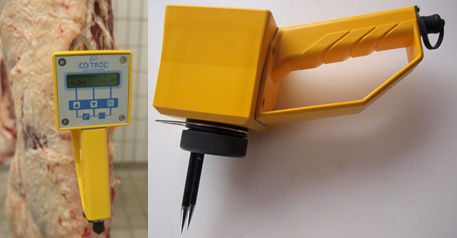

- Determination of the course of electrical conductivity and pulse impedance during meat maturation using a newly developed device

- Comparison of conductivity and pulse impedance with other meat quality parameters

(e.g. color, water binding capacity, shear force) - Determination of correlations between the mentioned parameters

- Check whether an assessment of meat quality is possible in practice using a device for determining electrical conductivity or pulse impedance and provides reliable results

- If it is suitable, the use of this device should be expanded into practice in collaboration with a cooperation partner